General Guidelines

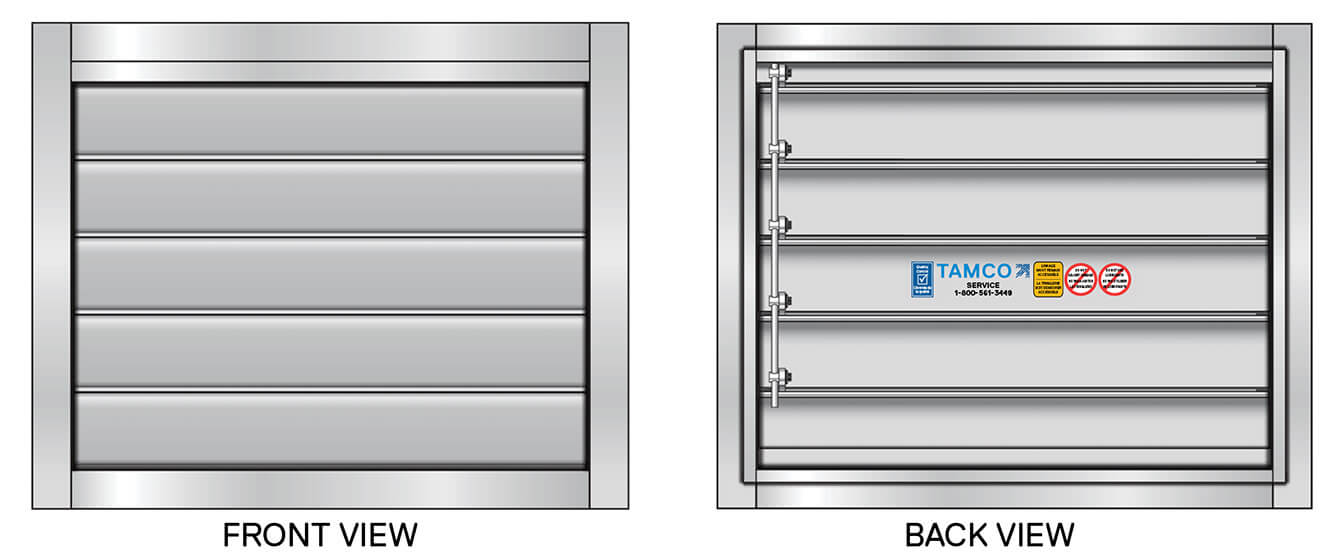

Medium-Duty Backdraft Dampers

- General

- Before Installation

- Documents

General Installation Notes:

- Backdraft dampers must be kept clean and dry. Store indoors to protect from dirt, dust and weather. Do not store at temperatures in excess of 100°F (38ºC).

- Do not stack backdraft dampers on top of or against each other.

- Backdraft dampers are to be handled and lifted by the frames only. Do not use the blades or linkage to lift backdraft dampers.

- Do not drop, drag or twist.

- Multiple-section assemblies will require sufficient people and appropriate rigging to lift units safely and without causing damage.

- Ensure that the opening or duct work is free of any obstructions and is adequately supported, so that damper operation is not adversely affected.

- The system must support the damper. The damper cannot support the system. Do not use the damper to square up duct. The opening must be plumb, straight, level, square, and sized correctly for the damper.

- The backdraft damper must not be twisted, compressed or stretched to fit the opening. Once installed, the blades must be free to move without binding. Use shims between the damper frame and the opening to prevent distortion or stretching of the backdraft damper.

- When installing fasteners (provided by others), they should be located so as not to interfere with blade operation.

- Consult engineering plans prior to installation to confirm airflow direction.

- Tamco recommends that backdraft dampers be installed at a minimum distance of one (1) fan diameter away from the fan, for custom air handler exhaust applications. AMCA 200 and AMCA 201 recommend a distance of one (1) duct diameter for each 1000 fpm in order to acheive uniform air at the backdraft damper. The type of fan and distance allowed between the fan and the damper will determine the air velocity profile the backdraft damper will be subjected to.

- When backdraft dampers are installed in the vertical plane, blades must always be horizontal.

- Series 7000, 7000 WT, and 7000 CW Backdraft Dampers can be installed in the vertical plane (Airflow Horizontal), or in the horizontal plane (Airflow Up).

- Only Series 7000 CW Counterweighted Backdraft Dampers can be installed in the horizontal plane with Airflow Down.

DO NOT ADJUST LINKAGE MECHANISM. IF PROBLEM STILL EXISTS AFTER VERIFICATION AND CORRECT ACTION, CALL Tamco CUSTOMER SERVICE AT 1-800-561-3449.

Tamco’s all-aluminum backdraft dampers are constructed with maintenance-free bearing and linkage components.

Caution: Never use any lubricants, such as grease or silicone, on Tamco backdraft dampers.

In applications where the humidity level is unusually elevated, or where there are extremely high levels of dust and dirt particles, Tamco recommends that the damper linkage and bearing system should be cleaned once a year. This can be done by blowing away dust using compressed air. If needed, a domestic-strength steam cleaner can be used to loosen dirt, which can then be blown out with compressed air, along with any remaining water droplets.

VERIFY BEFORE INSTALLATION:

- Before installing, inspect backdraft damper for possible damage caused in shipping, and that it has not been racked or twisted. Measure the damper from corner to corner to verify that it is square.

- If minor damage has occurred to frame corners or flanges, correct by bending or hammering back into position. Ensure correct realignment of repair, as bent or twisted frames might not mate properly with mounting angles, or additional damper sections.

- Do not install damper if damage is more than superficial, if uncertain as to extent of damage, or if damper does not operate correctly. CALL Tamco CUSTOMER SERVICE AT 1-800-561-3449.

- Compare items listed on packing list with materials received to ensure all parts of the shipment, including accessories, are accounted for.