Advanced Airflow Control for your High Density Data Centers

Simplify Airflow Maintenance

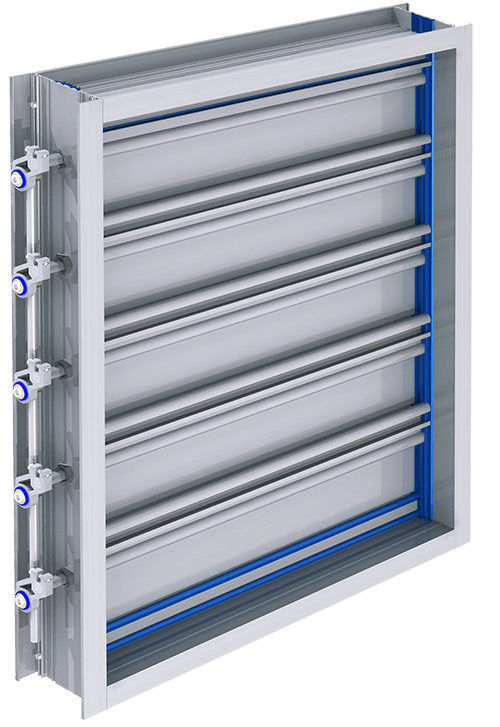

Tamco Dampers are no-touch engineered to remove maintenance from the equation, letting data center professionals focus maintenance efforts on what matters most, the IT equipment.

- Tamco dampers operate without lubricants or grease.

- Mechanically fastened blade and jamb seals maintain low-leakage integrity.

- Corrosion-resistant slip-proof linkage hardware requires no maintenance.

Increase Energy Efficiency

In data centers, efficiency and reliability are non-negotiable. Tamco dampers are engineered to support these demands by reducing energy waste, ensuring consistent airflow performance, and maintaining long-term durability.

- Tamco dampers deliver ultra-low leakage for consistent performance and lower energy costs, allowing you to hit your targets (PUE/WUE).

- Continuous cycle testing proves ultra-low leakage performance for over 2000 years of service (2 million cycles), an unrivaled long-term sustainable performance.

- Dedicated expert teams are continuously are ready to dial-in and develop a data center focused air management solution to enhance and improve performance.

Improve Climate Precision

In data centers, strict environmental conditions protect IT equipment and ensure uptime. Delivering to Service Level Agreements (SLA) for temperature, humidity, pressure, and airflow are critical to your meeting your operating conditions.

- Thermal break technology prevents condensation buildup on dampers, protecting critical IT equipment from moisture.

- Thermally insulated dampers maximize energy savings and improve thermal performance to ensure you meet your factory acceptance test (FAT, FWT).

- Optimal placement of thermal breaks will isolate warm and cold sides aisles and avoiding error states like rack stratification.

- No-touch dampers ensure your operating temperatures and flows are continually within specification.

- Avoid server and chip contamination (i.e. zinc whiskers) with all aluminum design.